Uncategorised

“Green” electronics: biodegradable and biocompatible materials and devices for sustainable future

https://pubs.rsc.org/en/content/articlelanding/2014/cs/c3cs60235d

“Green” electronics represents not only a novel scientific term but also an emerging area of research aimed at identifying compounds of natural origin and establishing economically efficient routes for the production of synthetic materials that have applicability in environmentally safe (biodegradable) and/or biocompatible devices. The ultimate goal of this research is to create paths for the production of human- and environmentally friendly electronics in general and the integration of such electronic circuits with living tissue in particular. Researching into the emerging class of “green” electronics may help fulfill not only the original promise of organic electronics that is to deliver low-cost and energy efficient materials and devices but also achieve unimaginable functionalities for electronics, for example benign integration into life and environment. This Review will highlight recent research advancements in this emerging group of materials and their integration in unconventional organic electronic devices.

Light future Ltd

New email for light future after their domain name change will be:

Microsphere Nanoscopy References

Endnote Format: Amer J Physics

sci-hub.do

1 E. Abbe, “Beitrage zur Theorie des Mikroskops und der mikroskopischen Wahrnehmung,” Archiv Microskop. Anat. 9, 413 (1873).

2 Lord Rayleigh, “XXXI. Investigations in optics, with special reference to the spectroscope,” Lond.Edinb.Dubl.Phil.Mag. 8 (49), 261-274 (1879).

3 CM Sparrow, “On Spectroscopic Resolving Power,” The Astrophysical Journal 44, 76 (1916).

4 William V Houston, “A compound interferometer for fine structure work,” Phys. Rev. 29 (3), 478 (1927).

5 G. Toraldo di Francia, “Super-gain antennas and optical resolving power,” Nuovo Cimento, Suppl. 9, 426-435 (1952).

6 B. Richards and E. Wolf, ” Electromagnetic diffraction in optical systems . II. Structure of the image field in an aplanatic system,” Proc. R. Soc. London Ser. A 253, 358 (1959).

7 D. W. Pohl, W. Denk, and M. Lanz, “Optical stethoscopy: image recording with resolution ladmda/20,” Applied Physics Letters 44 (7), 651-653 (1984).

8 D. W. Pohl, W. Denk, and M. Lanz, “Optical stethoscopy: Image recording with resolution λ/20,” Applied Physics Letters 44, 651-653 (1984).

9 S. W. Hell and J. Wichmann, “Breaking the diffraction resolution limit by stimulated emission: stimulated-emission-depletion fluorescence microscopy,” Optics letters 19 (11), 780-782 (1994).

10 M. Born and E. Wolf, Principles of optics. (Cambridge University Press, UK, 1999), 7 ed.

11 Robert C. Dunn, “Near-Field Scanning Optical Microscopy,” Chemical Reviews 99, 2891-2928 (1999).

12 Y. F. Lu, L. Zhang, W. D. Song, Y. W. Zheng, and B. S. Luk’yanchuk, “Laser writing of a subwavelength structure on silicon (100) surfaces with particle-enhanced optical irradiation,” Jetp Lett. 72 (9), 457-459 (2000).

13 J. B. Pendry, “Negative Refraction Makes a Perfect Lens,” Phys. Rev. Lett. 85, 3966 (2000).

14 Zhigang Chen, Allen Taflove, and Vadim Backman, “Photonic nanojet enhancement of backscattering of light by nanoparticles: a potential novel visible-light ultramicroscopy technique,” Optics Express 12, 1214 (2004).

15 Z. G. Chen, A. Taflove, and V. Backman, “Photonic nanojet enhancement of backscattering of light by nanoparticles: a potential novel visible-light ultramicroscopy technique,” Optics Express 12 (7), 1214-1220 (2004).

16 Z. G. Chen, A. Taflove, and V. Backman, “Photonic nanojets,” Ieee Antennas and Propagation Society Symposium, Vols 1-4 2004, Digest, 1923-1926 (2004).

17 B. S. Luk’Yanchuk, Z. B. Wang, W. D. Song, and M. H. Hong, “Particle on surface: 3D-effects in dry laser cleaning,” Appl Phys a-Mater 79 (4-6), 747-751 (2004).

18 R. J. Potton, “Reciprocity in optics,” Reports on Progress in Physics 67, 717-754 (2004).

19 N. Fang, H. Lee, C. Sun, and X. Zhang, “Sub-diffraction-limited optical imaging with a silver superlens,” Science 308 (5721), 534-537 (2005).

20 N Fang, H Lee, C Sun, and X Zhang, “Sub–Diffraction-Limited Optical Imaging with a Silver Superlens,” Science 308, 534-537 (2005).

21 A. V. Itagi and W. A. Challener, “Optics of photonic nanojets,” J Opt Soc Am A 22 (12), 2847-2858 (2005).

22 C. H. Li, G. W. Kattawar, P. W. Zhai, and P. Yang, “Electric and magnetic energy density distributions inside and outside dielectric particles illuminated by a plane electromagnetic wave,” Optics Express 13 (12), 4554-4559 (2005).

23 X. Li, Z. G. Chen, A. Taflove, and V. Backman, “Optical analysis of nanoparticles via enhanced backscattering facilitated by 3-D photonic nanojets,” Optics Express 13 (2), 526-533 (2005).

24 Z.B. Wang, National University of Singapore, 2005.

25 Z. Jacob, L. V. Alekseyev, and E. Narimanov, “Optical hyperlens: Far-field imaging beyond the diffraction limit,” Optics Express 14 (18), 8247-8256 (2006).

26 M. Gerlach, Y. P. Rakovich, and J. F. Donegan, “Nanojets and directional emission in symmetric photonic molecules,” Optics Express 15 (25), 17343-17350 (2007).

27 W. Guo, Z.B. Wang, L. Li, Z. Liu, B.S. Luk’yanchuk, P.L Crouse, and D.J. Whitehead, presented at the The 8th International Symposium on Laser Precision Microfabrication, 24-28 April 2007, University of Vienna, Vienna, Austria, 2007 (unpublished).

28 W. Guo, Z. B. Wang, L. Li, D. J. Whitehead, B. S. Luk’yanchuk, and Z. Liu, “Near-field laser parallel nanofabrication of arbitrary-shaped patterns,” Appl. Phys. Lett. 90, 243101 (2007).

29 Zhaowei Liu, Hyesog Lee, Yi Xiong, Cheng Sun, and Xiang Zhang, “Far-field optical hyperlens magnifying sub-diffraction-limited objects,” Science 315, 1686 (2007).

30 Z. W. Liu, H. Lee, Y. Xiong, C. Sun, and X. Zhang, “Far-field optical hyperlens magnifying sub-diffraction-limited objects,” Science 315 (5819), 1686-1686 (2007).

31 Paul R Selvin and Ha Taekjip, Single-molecule techniques: a laboratory manual. (Cold Spring Harbor Laboratory Press, 2007).

32 G. X. Chen, M. H. Hong, Y. Lin, Z. B. Wang, D. K. T. Ng, Q. Xie, L. S. Tan, and T. C. Chong, “Large-area parallel near-field optical nanopatterning of functional materials using microsphere mask,” Journal of Alloys and Compounds 449 (1-2), 265-268 (2008).

33 P. Ferrand, J. Wenger, A. Devilez, M. Pianta, B. Stout, N. Bonod, E. Popov, and H. Rigneault, “Direct imaging of photonic nanojets,” Optics Express 16 (10), 6930-6940 (2008).

34 Wei Guo, Zeng Bo Wang, Lin Li, Zhu Liu, Boris Luk’yanchuk, and David J Whitehead, “Chemical-assisted laser parallel nanostructuring of silicon in optical near fields,” Nanotechnology 19, 455302 (2008).

35 L. Li, W. Guo, Z.B. Wang, Z. Liu, D. J. Whitehead, and B.S. Luk’yanchuk, “Large Area Laser Nano-Texturing with User Defined Patterns”, in The 1st International Conference on Nanomanufacturing (nanoMan2008) (Singapore, 2008).

36 X. Zhang and Z. W. Liu, “Superlenses to overcome the diffraction limit,” Nat Mater 7 (6), 435-441 (2008).

37 Y. Zhou, M. H. Hong, J. Y. H. Fuh, L. Lu, B. S. Lukyanchuk, and Z. B. Wang, “Near-field enhanced femtosecond laser nano-drilling of glass substrate,” Journal of Alloys and Compounds 449 (1-2), 246-249 (2008).

38 A. Heifetz, S. C. Kong, A. V. Sahakian, A. Taflove, and V. Backman, “Photonic Nanojets,” J Comput Theor Nanos 6 (9), 1979-1992 (2009).

39 B. Huang, M. Bates, and X. Zhuang, “Super-resolution fluorescence microscopy,” Annual review of biochemistry 78, 993-1016 (2009).

40 Zengbo Wang, Tsung Sheng Kao, and Nikolay Zheludev, presented at the CLEO/Europe-EQEC, 2009 (unpublished).

41 Qian Zhao, Ji Zhou, Fuli Zhang, and Didier Lippens, “Mie resonance-based dielectric metamaterials,” Materials Today 12, 60-69 (2009).

42 Y. E. Geints, E. K. Panina, and A. A. Zemlyanov, “Control over parameters of photonic-nanojets of dielectric microspheres,” Opt Commun 283 (23), 4775-4781 (2010).

43 C. M. Ruiz and J. J. Simpson, “Detection of embedded ultra-subwavelength-thin dielectric features using elongated photonic nanojets,” Optics Express 18 (16), 16805-16812 (2010).

44 Costas M. Soukoulis and Martin Wegener, “Optical Metamaterials— More Bulky and Less Lossy,” Science 330, 1633-1634 (2010).

45 Z.B. Wang, J. Naveen, L. Li, and B.S. Luk’yanchuk, “A Review of Optical Near-Fields in Particle/Tip-assisted Laser Nanofabrication,” P.I.Mech. Eng. C-J. Mec. 224, 1113-1127 (2010).

46 D. Grojo, L. Charmasson, A. Pereira, M. Sentis, and P. Delaporte, “Monitoring Photonic Nanojets from Microsphere Arrays by Femtosecond Laser Ablation of Thin Films,” J Nanosci Nanotechno 11 (10), 9129-9135 (2011).

47 Xiang Hao, Cuifang Kuang, Xu Liu, Haijun Zhang, and Yanghui Li, “Microsphere based microscope with optical super-resolution capability,” Applied Physics Letters 99 (20), 203102 (2011).

48 Ashfaq Khan, Zengbo Wang, Mohammad A Sheikh, and Lin Li, “Laser Sub-Micron Patterning of Rough Surfaces by Micro-Particle Lens Arrays,” International Journal of Manufacturing, Materials, and Mechanical Engineering (IJMMME) 1 (3), 9 (2011).

49 Ashfaq Khan, Zengbo Wang, Mohammad A. Sheikh, David Whitehead, and Lin Li, “Laser micro/nano patterning of hydrophobic surface by contact particle lens array,” Appl. Surf. Sci. 258, 774-779 (2011).

50 M. S. Kim, T. Scharf, S. Muhlig, C. Rockstuhl, and H. P. Herzig, “Gouy phase anomaly in photonic nanojets,” Applied Physics Letters 98 (19), 191114 (2011).

51 Yongmin Liu and Xiang Zhang, “Metamaterials: a new frontier of science and technology,” Chemical Society Reviews 40, 2494 (2011).

52 Costas M. Soukoulis and Martin Wegener, “Past achievements and future challenges in the development of three-dimensional photonic metamaterials,” Nat. Photonics 5, 524-530 (2011).

53 Zengbo Wang, Wei Guo, Lin Li, Boris Luk’yanchuk, Ashfaq Khan, Zhu Liu, Zaichun Chen, and Minghui Hong, “Optical virtual imaging at 50 nm lateral resolution with a white-light nanoscope,” Nat Commun 2, 218 (2011).

54 Z. B. Wang and L. Li, “White-light microscopy could exceed 50 nm resolution,” Laser Focus World 47 (7), 61-64 (2011).

55 Jon Cartwright, “Defeating diffraction,” Physics world 25 (5), 29-34 (2012).

56 A. Darafsheh, G. F. Walsh, L. Dal Negro, and V. N. Astratov, “Optical super-resolution by high-index liquid-immersed microspheres,” Applied Physics Letters 101 (14), 141128 (2012).

57 D. Lu and Z. Liu, “Hyperlenses and metalenses for far-field super-resolution imaging,” Nat Commun 3, 1205 (2012).

58 D. McCloskey, J. J. Wang, and J. F. Donegan, “Low divergence photonic nanojets from Si3N4 microdisks,” Optics Express 20 (1), 128-140 (2012).

59 E. T. Rogers, J. Lindberg, T. Roy, S. Savo, J. E. Chad, M. R. Dennis, and N. I. Zheludev, “A super-oscillatory lens optical microscope for subwavelength imaging,” Nat Mater 11 (5), 432-435 (2012).

60 A. Vlad, I. Huynen, and S. Melinte, “Wavelength-scale lens microscopy via thermal reshaping of colloidal particles,” Nanotechnology 23 (28), 285708 (2012).

61 V. Yannopapas, “Photonic nanojets as three-dimensional optical atom traps: A theoretical study,” Opt Commun 285 (12), 2952-2955 (2012).

62 H. Guo, Y. Han, X. Weng, Y. Zhao, G. Sui, Y. Wang, and S. Zhuang, “Near-field focusing of the dielectric microsphere with wavelength scale radius,” Opt. Express 21 (2), 2434-2443 (2013).

63 X. Hao, X. Liu, C. Kuang, Y. Li, Y. Ku, H.Zhang, H. Li, and L. Tong, “Far-field super-resolution imaging using near-field illumination by micro-fiber,” Appl. Phys. Lett. 102, 013104 (2013).

64 Alexander V. Kildishev, Alexandra Boltasseva, and Vladimir M. Shalaev, “Planar Photonics with Metasurfaces,” Nat Mater 339, 1232009 (2013).

65 L. A. Krivitsky, J. J. Wang, Z. B. Wang, and B. Luk’yanchuk, “Locomotion of microspheres for super-resolution imaging,” Sci Rep-Uk 3, 3501 (2013).

66 S. Lee, L. Li, Z. Wang, W. Guo, Y. Yan, and T. Wang, “Immersed transparent microsphere magnifying sub-diffraction-limited objects,” Applied optics 52 (30), 7265-7270 (2013).

67 Lin Li, Wei Guo, Yinzhou Yan, Seoungjun Lee, and Tao Wang, “Label-free super-resolution imaging of adenoviruses by submerged microsphere optical nanoscopy,” Light: Science & Applications 2 (9), e104 (2013).

68 Z.B. Wang, Y. Zhou, and Boris Luk’yanchuk, “Near-field focusing of dielectric microspheres: Super-resolution and field-invariant parameter scaling,” arXiv:1304.4139v2 (2013).

69 Hui Yang, Norman Moullan, Johan Auwerx, and Martin A. M. Gijs, “Super-Resolution Biological Microscopy Using Virtual Imaging by a Microsphere Nanoscope,” Small 10 (9), 1712–1718 (2013).

70 V.N. Astratov and A. Darafsheh, “Methods and systems for super-resolution optical imaging usinghigh-index of refraction microspheres and micro-cylinders,,” US patent application 2014/0355108 A1 published on December 4, 2014 (2014).

71 Arash Darafsheh, Nicholaos I. Limberopoulos, John S. Derov, Dennis E. Walker, and Vasily N. Astratov, “Advantages of microsphere-assisted super-resolution imaging technique over solid immersion lens and confocal microscopies,” Applied Physics Letters 104 (6), 061117 (2014).

72 Seoungjun Lee, Lin Li, and Zengbo Wang, “Optical resonances in microsphere photonic nanojets,” Journal of Optics 16 (1), 015704 (2014).

73 V. M. Sundaram and S. B. Wen, “Analysis of deep sub-micron resolution in microsphere based imaging,” Applied Physics Letters 105 (20) (2014).

74 Zengbo Wang, “Improvements in and Relating to Lenses,” PCT/GB2014/052578 (priority date: 2013-AUG-23) (2014).

75 Y. Yan, L. Li, C. Feng, W.Guo, S.Lee, and M.H.Hong, “Microsphere-Coupled Scanning Laser Confocal Nanoscope for Sub-Diffraction-Limited Imaging at 25 nm Lateral Resolution in the Visible Spectrum,” ACS Nano 8 (2), 1809-1816 (2014).

76 Hui Yang, Norman Moullan, Johan Auwerx, and Martin A.M. Gijs, “Super-resolution biological microscopy using virtual imaging by a microsphere nanoscope,” Small 10, 1712-1718 (2014).

77 Nanfang Yu and Federico Capasso, “Flat optics with designer metasurfaces,” Nat Mater 13, 139-150 (2014).

78 Kenneth W. Allen, Navid Farahi, Yangcheng Li, Nicholaos I. Limberopoulos, Dennis E. Walker, Augustine M. Urbas, Vladimir Liberman, and Vasily N. Astratov, “Super-resolution microscopy by movable thin-films with embedded microspheres: Resolution analysis,” Annalen der Physik 527 (7-8), 513-522 (2015).

79 Shandra J. Corbitt, Mathieu Francoeur, and Bart Raeymaekers, “Implementation of optical dielectric metamaterials: A review,” Journal of Quantitative Spectroscopy and Radiative Transfer 158, 3-16 (2015).

80 Arash Darafsheh, Consuelo Guardiola, Averie Palovcak, Jarod C Finlay, and Alejandro Cárabe, “Optical super-resolution imaging by high-index microspheres embedded in elastomers,” Optics letters 40 (1), 5-8 (2015).

81 Y. E. Geints, A. A. Zemlyanov, and E. K. Panina, “Characteristics of photonic jets from microcones,” Opt Spectrosc+ 119 (5), 849-854 (2015).

82 Thanh Xuan Hoang, Yubo Duan, Xudong Chen, and George Barbastathis, “Focusing and imaging in microsphere-based microscopy,” Optics express 23 (9), 12337-12353 (2015).

83 Jacob B. Khurgin, “How to deal with the loss in plasmonics and metamaterials,” Nature Nanotechnology 10, 2-6 (2015).

84 B. S. Luk’yanchuk, N. V. Voshchinnikov, R. Paniagua-Dominguez, and A. I. Kuznetsov, “Optimum Forward Light Scattering by Spherical and Spheroidal Dielectric Nanoparticles with High Refractive Index,” Acs Photonics 2 (7), 993-999 (2015).

85 I. V. Minin, O. V. Minin, and Y. E. Geints, “Localized EM and photonic jets from non-spherical and non-symmetrical dielectric mesoscale objects: Brief review,” Annalen Der Physik 527 (7-8), 491-497 (2015).

86 I. V. Minin, O. V. Minin, V. Pacheco-Pena, and M. Beruete, “Localized photonic jets from flat, three-dimensional dielectric cuboids in the reflection mode,” Optics letters 40 (10), 2329-2332 (2015).

87 Feifei Wang, Hok Sum Sam Lai, Lianqing Liu, Pan Li, Haibo Yu, Zhu Liu, Yuechao Wang, and Wen Jung Li, “Super-resolution endoscopy for real-time wide-field imaging,” Optics express 23 (13), 16803-16811 (2015).

88 H. Yang, M. Cornaglia, and M. A. M. Gijs, “Photonic Nanojet Array for Fast Detection of Single Nanoparticles in a Flow,” Nano Letters 15 (3), 1730-1735 (2015).

89 Nikolay I. Zheludev, “Obtaining optical properties on demand,” Science 348, 973-974 (2015).

90 Haier Zhu, Bing Yan, Zengbo Wang, and Limin Wu, “Synthesis and super-resolution imaging performance of refractive-index-controllable microsphere superlens,” J. Mater. Chem. C 3, 10907-10915 (2015).

91 Alexander N. Cartwright, Dan V. Nicolau, Dror Fixler, V. N. Astratov, A. V. Maslov, K. W. Allen, N. Farahi, Y. Li, A. Brettin, N. I. Limberopoulos, D. E. Walker, A. M. Urbas, V. Liberman, and M. Rothschild, “Fundamental limits of super-resolution microscopy by dielectric microspheres and microfibers”, in Nanoscale Imaging, Sensing, and Actuation for Biomedical Applications XIII (2016).

92 W. Fan, B. Yan, Z. B. Wang, and L. M. Wu, “Three-dimensional all-dielectric metamaterial solid immersion lens for subwavelength imaging at visible frequencies,” Sci Adv 2 (8) (2016).

93 Saman Jahani and Zubin Jacob, “All-dielectric metamaterials,” Nature Nanotechnology 11, 23-36 (2016).

94 Jinxing Li, Wenjuan Liu, Tianlong Li, Isaac Rozen, Jason Zhao, Babak Bahari, Boubacar Kante, and Joseph Wang, “Swimming Microrobot Optical Nanoscopy,” Nano Letters 16, 6604-6609 (2016).

95 Yu Chao Li, Hong Bao Xin, Hong Xiang Lei, Lin Lin Liu, Yan Ze Li, Yao Zhang, and Bao Jun Li, “Manipulation and detection of single nanoparticles and biomolecules by a photonic nanojet,” Light: Science and Applications 5, 1-9 (2016).

96 C. Y. Liu and C. C. Li, “Photonic nanojet induced modes generated by a chain of dielectric microdisks,” Optik 127 (1), 267-273 (2016).

97 J. N. Monks, B. Yan, N. Hawkins, F. Vollrath, and Z. B. Wang, “Spider Silk: Mother Nature’s Bio-Superlens,” Nano Letters 16 (9), 5842-5845 (2016).

98 Feifei Wang, Lianqing Liu, Peng Yu, Zhu Liu, Haibo Yu, Yuechao Wang, and Wen Jung Li, “Three-dimensional super-resolution morphology by near-field assisted white-light interferometry,” Sci Rep-Uk 6, 24703 (2016).

99 F. F. Wang, L. Q. Liu, H. B. Yu, Y. D. Wen, P. Yu, Z. Liu, Y. C. Wang, and W. J. Li, “Scanning superlens microscopy for non-invasive large field-of-view visible light nanoscale imaging,” Nature Communications 7 (2016).

100 Z.B. Wang, “Microsphere super-resolution imaging”, in Nanoscience, edited by John Thomas Paual O Brien (Royal Society of Chemistry, 2016), Vol. 3, pp. 193-210.

101 Hui Yang, Raphaël Trouillon, Gergely Huszka, and Martin AM Gijs, “Super-resolution imaging of a dielectric microsphere is governed by the waist of its photonic nanojet,” Nano Lett 16 (8), 4862-4870 (2016).

102 A. Bezryadina, J. X. Li, J. X. Zhao, A. Kothambawala, J. Ponsetto, E. Huang, J. Wang, and Z. W. Liu, “Localized plasmonic structured illumination microscopy with an optically trapped microlens,” Nanoscale 9 (39), 14907-14912 (2017).

103 Ivan Kassamakov, Sylvain Lecler, Anton Nolvi, Audrey Leong-Hoï, Paul Montgomery, and Edward Hæggström, “3D super-resolution optical profiling using microsphere enhanced Mirau interferometry,” Sci Rep-Uk 7 (1), 3683 (2017).

104 Boris S Luk’yanchuk, Ramón Paniagua-Domínguez, Igor Minin, Oleg Minin, and Zengbo Wang, “Refractive index less than two: photonic nanojets yesterday, today and tomorrow,” Optical Materials Express 7 (6), 1820-1847 (2017).

105 I. Mahariq, I. H. Giden, H. Kurt, O. V. Minin, and I. V. Minin, “Strong electromagnetic field localization near the surface of hemicylindrical particles,” Opt Quant Electron 49 (12) (2017).

106 Alexey V. Maslov and Vasily N. Astratov, “Optical nanoscopy with contact Mie-particles: Resolution analysis,” Applied Physics Letters 110 (26) (2017).

107 Fei Qin, Kun Huang, Jianfeng Wu, Jinghua Teng, Cheng‐Wei Qiu, and Minghui Hong, “A Supercritical Lens Optical Label‐Free Microscopy: Sub‐Diffraction Resolution and Ultra‐Long Working Distance,” Advanced Materials 29 (8), 1602721 (2017).

108 Zengbo Wang, “n=1.5 nano microsphere light focusing”, (2017), pp. https://www.youtube.com/watch?v=YsEeVqjXSrg.

109 Zengbo Wang, “n=1.5 cylinder”, (2017), pp. https://www.youtube.com/watch?v=rkmyQD55QuQ.

110 Bing Yan, Zengbo Wang, Alan L Parker, Yu-kun Lai, P John Thomas, Liyang Yue, and James N Monks, “Superlensing microscope objective lens,” Appl. Opt. 56 (11), 3142-3147 (2017).

111 Y. E. Geints, A. A. Zemlyanov, O. V. Minin, and I. V. Minin, “Systematic study and comparison of photonic nanojets produced by dielectric microparticles in 2D-and 3D-spatial configurations,” Journal of Optics 20 (6) (2018).

112 K. Huang, F. Qin, H. Liu, H. Ye, C. W. Qiu, M. Hong, B. Luk’yanchuk, and J. Teng, “Planar Diffractive Lenses: Fundamentals, Functionalities, and Applications,” Adv. Mater. 30 (26), e1704556 (2018).

113 C. Y. Liu, O. V. Minin, and I. V. Minin, “First experimental observation of array of photonic jets from saw-tooth phase diffraction grating,” Epl-Europhys Lett 123 (5) (2018).

114 Liyang Yue, Oleg V Minin, Zengbo Wang, James N Monks, Alexander S Shalin, and Igor V Minin, “Photonic hook: a new curved light beam,” Optics letters 43 (4), 771-774 (2018).

115 L. Y. Yue, B. Yan, J. N. Monks, R. Dhama, Z. B. Wang, O. V. Minin, and I. V. Minin, “Intensity-Enhanced Apodization Effect on an Axially Illuminated Circular-Column Particle-Lens,” Annalen Der Physik 530 (2) (2018).

116 L. Y. Yue, B. Yan, J. N. Monks, R. Dhama, Z. B. Wang, O. V. Minin, and I. V. Minin, “Photonic Jet by a Near-Unity-Refractive-Index Sphere on a Dielectric Substrate with High Index Contrast,” Annalen Der Physik 530 (6) (2018).

117 Zengbo Wang and Boris Luk’yanchuk, “Super-resolution imaging and microscopy by dielectric particle-lenses”, in Label-Free Super-Resolution Microscopy, edited by Vasily Astratov (Springer, 2019).

118 M. W. Tang, X. W. Liu, Z. Wen, F. H. Lin, C. Meng, X. Liu, Y. G. Ma, and Q. Yang, “Far-Field Superresolution Imaging via Spatial Frequency Modulation,” Laser Photonics Rev 14 (11) (2020).

Far-Field Superresolution Imaging via Spatial Frequency Modulation

Mingwei Tang, Xiaowei Liu, Zhong Wen, Feihong Lin, Chao Meng, Xu Liu, Yaoguang Ma, Qing YangFirst published: 03 September 2020 https://doi.org/10.1002/lpor.201900011Citations: 3SECTIONSPDFTOOLSSHARE

Abstract

The diffraction limit substantially impedes the resolution of the conventional optical microscope. Under traditional illumination, the high-spatial-frequency light corresponding to the subwavelength information of objects is located in the near-field in the form of evanescent waves, and thus not detectable by conventional far-field objectives. Recent advances in nanomaterials and metamaterials provide new approaches to break this limitation by utilizing large-wavevector evanescent waves. Here, a comprehensive review of this emerging and fast-growing field is presented. The current superresolution imaging techniques based on evanescent-wave-assisted spatial frequency modulation, including hyperlens, microsphere lens, and evanescent field-illuminated spatial frequency shift microscopy, are illustrated. They are promising in investigating unobserved details and processes in fields such as medicine, biology, and material research. Some current challenges and future possibilities of these superresolution methods are also discussed.

Laser-based technologies for green manufacturing (Photonics – Made in Europe Partnerships)

General informationProgrammeHorizon Europe Framework Programme (HORIZON)CallTWIN GREEN AND DIGITAL TRANSITION 2021 (HORIZON-CL4-2021-TWIN-TRANSITION-01)See budget overview

Type of actionHORIZON-RIA HORIZON Research and Innovation ActionsType of MGAHORIZON Action Grant Budget-Based [HORIZON-AG]

Deadline modelsingle-stageOpening date22 June 2021Deadline date23 September 2021 17:00:00 Brussels timeOpen for submissionTopic descriptionExpectedOutcome:

Projects are expected to contribute to the following outcomes:

- Reinforcing European industry as leader in agile, green manufacturing through the application of laser-based technologies;

- Improving the agility of industrial production by making processes more versatile, simpler to reconfigure and more efficient to control through data exchange;

- Improving the environmental sustainability of industrial production towards ‘first-time right’ processes with 30% lower consumption of resources compared to the state of the art.

Scope:

Machine tools include various laser-based technologies such as milling, turning, grinding, laser processing, surface treatment, sintering, forming and additive manufacturing. Projects funded under this topic should integrate state-of-the-art high-power lasers and tailored beams together with quality sensors and real time monitoring systems into advanced manufacturing and re-manufacturing tools.

Known research challenges are amongst others the transmission of very high average and peak power laser radiation without loss or distortion including in the ultraviolet, mid and far infrared spectral range, powerful optical fibres, programmable beam guidance, maximum positional flexibility, free choice of energy distribution, rapid quantitative feedback and beam distribution systems with sub-micrometre resolution and high performance. A further research challenge is the integration of quality sensors in laser-based manufacturing. These produce a vast amount of data with a need for dedicated signal processing. Edge devices with self-learning algorithms should be developed that can handle the computing requirements in the time required by the system to react with a feedback control action.

Project consortia should comprise research institutes, technology suppliers and users. They should demonstrate the benefits to the targeted technologies in at least three use cases.

Proposals submitted under this topic should include a business case and exploitation strategy, as outlined in the introduction to this Destination.

Research must build on existing standards or contribute to standardisation. Interoperability for data sharing should be addressed. Additionally, a strategy for skills development should be presented, associating social partners when relevant.

All projects should build on or seek collaboration with existing projects and develop synergies with other relevant European, national or regional initiatives, funding programmes and platforms.

This topic implements the co-programmed European Partnership Made in Europe and activities proposed by the Photonics Europe Partnership.Specific Topic Conditions:

Activities are expected to start at TRL 3-4 and achieve TRL 6 by the end of the project – see General Annex B.Cross-cutting Priorities:

Socio-economic science and humanities

Co-programmed European Partnerships

Co-programmed European Partnerships

show less…DestinationClimate neutral, circular and digitised production

This destination will directly support the following Key Strategic Orientations, as outlined in the Strategic Plan:

- KSO C, ‘Making Europe the first digitally led circular, climate-neutral and sustainable economy through the transformation of its mobility, energy, construction and production systems.’

- KSO A, ‘Promoting an open strategic autonomy by leading the development of key digital, enabling and emerging technologies, sectors and value chains to accelerate and steer the digital and green transitions through human-centred technologies and innovations.’

- KSO D, ‘Creating a more resilient, inclusive and democratic European society, prepared and responsive to threats and disasters, addressing inequalities and providing high-quality health care, and empowering all citizens to act in the green and digital transitions.’

Proposals for topics under this Destination should set out a credible pathway to the following expected impact of Cluster 4:

- Global leadership in clean and climate-neutral industrial value chains, circular economy and climate-neutral digital systems and infrastructures (networks, data centres), through innovative production and manufacturing processes and their digitisation, new business models, sustainable-by-design advanced materials and technologies enabling the switch to decarbonisation in all major emitting industrial sectors, including green digital technologies.

Accelerating the twin green and digital transitions will be key to building a lasting and prosperous growth, in line with the EU’s new growth strategy, the European Green Deal. Europe’s ability to lead the twin transitions will require new technologies, with investment and innovation to match. Research and innovation will be fundamental to create the new products, services and business models needed to sustain or enable EU industrial leadership and competitiveness, and to create new markets for climate neutral and circular products. The shift towards a sustainable and inclusive economic model will be further enabled by the broader diffusion and uptake of digital and clean technologies across key sectors.

As Europe transitions towards climate neutrality, some sectors will have to make bigger and more transformative changes than others, due to their centrality in a variety of value chains and their large potential contribution to emissions reductions. Activities under this Destination focus on the twin green and digital transition providing a green productivity premium to discrete manufacturing, construction and energy-intensive industries, including process industries. This will make an essential and significant contribution to achieving climate neutrality in the European Union by 2050, and to the achievement of a circular economy. It will also enhance the Union’s open strategic autonomy with regard to the underlying technologies. To achieve these goals, the activities in this Destination are complementary to those in Destination 2, which will enhance open strategic autonomy in key strategic value chains for a resilient industry.

The gross added value of the European manufacturing sector is EUR 2,076 billion (2019). The sector employs more than 30 million people in the Union and represents 22% of the world’s manufacturing output. The Union’s trade surplus in manufactured goods is EUR 421 billion (2019). Similarly, the construction ecosystem (driven mainly by SMEs) offers 22 million jobs and contributes 10.5% of EU-27 global value added[[‘Updating the 2020 New Industrial Strategy: Building a stronger Single Market for Europe’s recovery’, COM(2021)350 final and associated Staff Working Documents]]. However, the manufacturing and construction sectors must significantly reduce their pollution and waste, and increase their recycling. Moreover, the potential of digital technologies is underused in manufacturing industry, e.g. 12% of EU enterprises use big data technologies and only 1 out of 5 SMEs is highly digitised, and in construction, which remains one of the least digitised sectors with a notable underinvestment in R&D.[[The digital intensity of the construction sector is below 10%, meaning that the sector has a very slow absorption rate of digital technologies, according to the Digital Transformation Scoreboard 2018, https://ec.europa.eu/information_society/newsroom/image/document/2018-20/4_desi_report_integration_of_digital_technology_B61BEB6B-F21D-9DD7-72F1FAA836E36515_52243.pdf]] A key issue for the manufacturing sector is that its complex supply and value chains are heavily affected by the current pandemic crisis, and the sector needs to further develop resilience against financial and technical disruptions.

In addition, the Union’s process industries are important to its economy, its resilience and its environmental credentials. Process industries are responsible for a turnover of > 2 trillion, 8.5 million direct jobs and 20 million indirect jobs. They represent 0.5 million enterprises and 5 % of the EU27 GDP. The process industry however faces two key challenges: a strong global competition, and an environmental challenge. In particular, energy-intensive industries are resource intensive, using extensive amounts of raw materials (often imported and fossil based). In their operations, they generate large amounts of waste, 20% of global greenhouse gases (GHG) but also pollutants. The industries need to transform itself to decrease GHG and pollutant emissions, its resource utilisation and its overall environmental impact. It will have to achieve climate neutrality, near zero waste, zero pollution and zero landfill by 2050 at the latest. By 2030, decisive steps need to be taken given the long investment cycles these industries are facing. As the process industry is transforming primary raw materials into materials ready for use by the manufacturing industry, it will play a key role in the pathways toward circularity of materials by transforming industrial and end-of-life waste into secondary raw materials leading to the same quality output in the newly produced materials.

In the first Work Programme, outcomes of R&I investments in the long-term will focus on the following impacts:

- Accelerate the twin green and digital transition of the manufacturing and construction sectors;

- Create a new green, flexible and digital way to build and produce goods. This will lead to sustainable, flexible, responsive and resilient factories and value chains, enabled by digitisation, AI, data sharing, advanced robotics and modularity. At the same time it will help reduce CO2 emissions and waste in these sectors, and enhance the durability, reparability and re-cycling of products/components. It will also ensure better and more efficient use of construction-generated data to sustain competitiveness and greening of the sector;

- Make the jobs of the humans working in the manufacturing and construction sectors more attractive and safer, and point the way to opportunities for upskilling;

- Set out a credible pathway to contributing to climate neutral, circular and digitalised energy intensive industries;

- Increase productivity, innovation capacity, resilience, sustainability and global competitiveness of European energy intensive industries. This includes as many as possible new large hubs for circularity by 2025 (TRL 7 or above); developing sustainable ways for circular utilisation of waste streams and CO2/CO streams; and electrifying industry to enable and foster a switch to a renewable energy system;

- Contribute to a substantial reduction of waste and CO2 emissions, turning them into alternative feedstocks to replace fossil-based raw materials and decrease reliance on imports.

In order to achieve the expected outcomes, for particular topics international cooperation is clearly not mandatory but advised with some regions or countries to get internationally connected and add additional specific expertise and value to the activities.

In line with the European Green Deal objectives, research and innovation activities should comply with the ‘do no significant harm’ principle[[as per Article 17 of Regulation (EU) No 2020/852 on the establishment of a framework to facilitate sustainable investment (EU Taxonomy Regulation)]]. Compliance needs to be assessed both for activities carried out during the course of the project as well as the expected life cycle impact of the innovation at a commercialisation stage (where relevant). The robustness of the compliance must be customised to the envisaged TRL of the project. In this regard, the potential harm of Innovation Actions contributing to the European Green Deal will be monitored throughout the project duration.

To achieve wider effects activities beyond R&I investments will be needed. Three co-programmed partnerships will enhance dissemination, community building and foster spillover effects: Made in Europe for the manufacturing sectors, Clean Steel and Processes4Planet for the energy intensive industries. This destination has strong links to other clusters in Pillar II, notably Cluster 5 for the activities related to the integration of renewables and thermal energy management in industry, and with the European Innovation Council and Pillar III of Horizon Europe given the strong role of SMEs in the development of the innovations planned. Synergies will be sought to access blended funding and finance from other EU programmes; testing and deployment activities under the Digital Europe Programme (DEP); links to the EIT (Manufacturing and Digital KICs); and links to the thematic smart specialisation platform on industrial modernisation.

Much of the research and innovation supported under this Destination may serve as a cradle for the New European Bauhaus: this is about designing sustainable ways of living, situated at the crossroads between art, culture, social inclusion, science and technology. This includes R&I on manufacturing, construction, advanced materials and the circular economy approaches.

Business cases and exploitation strategies for industrialisation: This section applies only to those topics in this Destination, for which proposals should demonstrate the expected impact by including a business case and exploitation strategy for industrialisation.

The business case should demonstrate the expected impact of the proposal in terms of enhanced market opportunities for the participants and enhanced manufacturing capacities in the EU, in the short to medium term. It should describe the targeted market(s); estimated market size in the EU and globally; user and customer needs; and demonstrate that the solutions will match the market and user needs in a cost-effective manner; and describe the expected market position and competitive advantage.

The exploitation strategy should identify obstacles, requirements and necessary actions involved in reaching higher TRLs, for example: matching value chains, enhancing product robustness; securing industrial integrators; and user acceptance.

For TRLs 7-8, a credible strategy to achieve future full-scale manufacturing in the EU is expected, indicating the commitments of the industrial partners after the end of the project.

Activities beyond R&I investments will be needed to realise the expected impacts: these include the further development of skills and competencies (also via the European Institute of Innovation and Technology, in particular EIT Manufacturing); and the use of financial products under the InvestEU Fund for further commercialisation of R&I outcomes.

Where relevant, in the context of skills, it is recommended to develop training material to endow workers with the right skillset in order to support the uptake and deployment of new innovative products, services, and processes developed in the different projects. This material should be tested and be scalable, and can potentially be up-scaled through the European Social Fund Plus (ESF+). This will help the European labour force to close the skill gaps in the relevant sectors and occupational groups and improve employment and social levels across the EU and associated countries.

The topics serving these objectives are structured as follows:

- Green, flexible and advanced manufacturing

- Advanced digital technologies for manufacturing

- A new way to build, accelerating disruptive change in construction

- Hubs for circularity, a stepping stone towards climate neutrality and circularity in industry

- Enabling circularity of resources in the process industries, including waste, water and CO2/CO

- Integration of Renewables and Electrification in process industry

show more…Topic conditions and documents

General conditions

1. Admissibility conditions: described in Annex A and Annex E of the Horizon Europe Work Programme General Annexes.

Proposal page limits and layout: described in Part B of the Application Form available in the Submission System.

2. Eligible countries: described in Annex B of the Work Programme General Annexes.

A number of non-EU/non-Associated Countries that are not automatically eligible for funding have made specific provisions for making funding available for their participants in Horizon Europe projects. See the information in the Horizon Europe Programme Guide.

3. Other eligibility conditions: described in Annex B of the Work Programme General Annexes.

4. Financial and operational capacity and exclusion: described in Annex C of the Work Programme General Annexes.

5. Evaluation and award:

Award criteria, scoring and thresholds are described in Annex D of the Work Programme General Annexes.

Submission and evaluation processes are described in Annex F of the Work Programme General Annexes and the Online Manual.

Indicative timeline for evaluation and grant agreement: described in Annex F of the Work Programme General Annexes.

6. Legal and financial set-up of the grants: described in Annex G of the Work Programme General Annexes.

Specific conditions

7. Specific conditions: described in the specific topic of the Work Programme.

Documents

Call documents:

Standard application form (HE RIA, IA) — call-specific application form is available in the Submission System

Standard evaluation form (HE RIA, IA) — will be used with the necessary adaptations

HE General MGA v1.0 — MGA

Additional documents:

HE Main Work Programme 2021–2022 – 1. General Introduction

HE Main Work Programme 2021–2022 – 7. Digital, Industry and Space

HE Main Work Programme 2021–2022 – 13. General Annexes

HE Framework Programme and Rules for Participation Regulation 2021/695

HE Specific Programme Decision 2021/764

Rules for Legal Entity Validation, LEAR Appointment and Financial Capacity Assessment

EU Grants AGA — Annotated Model Grant Agreement

Funding & Tenders Portal Online Manual

λ/12 Super Resolution Achieved in Maskless Optical Projection Nanolithography for Efficient Cross-Scale Patterning

- Yu-Huan Liu

- Yuan-Yuan Zhao

- Feng Jin

- Xian-Zi Dong*

- Mei-Ling Zheng*

- Zhen-Sheng Zhao

- Xuan-Ming Duan*

Abstract

The emerging demand for device miniaturization and integration prompts the patterning technique of micronano-cross-scale structures as an urgent desire. Lithography, as a sufficient patterning technique, has been playing an important role in achieving functional micronanoscale structures for decades. As a promising alternative, we have proposed and demonstrated the maskless optical projection nanolithography (MLOP-NL) technique for efficient cross-scale patterning. A minimum feature size of 32 nm, which is λ/12 super resolution breaking the optical diffraction limit, has been achieved by a single exposure. Furthermore, multiscale two-dimensional micronano-hybrid structures with the size over hundreds of micrometers and the precision at tens of nanometers have been fabricated by simply controlling the exposure conditions. The proposed MLOP-NL technique provides a powerful tool for achieving cross-scale patterning with both large-scale and precise configuration with high efficiency, which can be potentially used in the fabrication of multiscale integrated microsystems.

Cite this: Nano Lett. 2021, 21, 9, 3915–3921Publication Date:May 3, 2021https://doi.org/10.1021/acs.nanolett.1c00559

Rayleigh Criterion

Rayleigh Criterion | COSMOS (swin.edu.au)

The Rayleigh criterion specifies the minimum separation between two light sources that may be resolved into distinct objects.

When a point source, such as a star, is observed through a telescope with a circular aperture, the image is not a point source – it is a disk surrounded by a number of very faint rings. These rings are produced by Fraunhofer diffraction of the light by the circular aperture. In this case, the irradiance, I(θ), is

![$ I(\theta) = I(0)\left[\frac{2J_1(ka\sin\theta)}{ka\sin\theta}\right]^2 $](https://astronomy.swin.edu.au/cosmos/files/tex/5f7f0243103e8037d89cb925ef16b49e737faef5.png)

where I(0) is the peak irradiance at the centre of the diffraction pattern, D=2a is the diameter of the aperture, k is the wave number and J1(u) is the first order Bessel function.

The central region of the profile, from the peak to the first minimum, is called the Airy disk. It has an angular radius given by:

| or |

using the small angle approximation that sin θ ≈ θ (where θ is measured in radians).

If we have two point or more point sources very close together, their Airy disks will overlap. It is only possible to resolve a pair of sources if the central peaks of the two diffraction patterns are no closer than the radius of the Airy disk. This is known as the Rayleigh Criterion and was named for John William Strut, the 3rd Baron Rayleigh.

| These two stars are clearly resolvable, as their Airy disks do not overlap. | These two stars are just resolvable – although the Airy disks overlap, they are separated by more than the Airy disk radius. | These two stars are not resolvable. |

| The overlapping irradiance patterns from two stars. |

Software KK

The software from the division is free to use. The coder should however be acknowledged if the use results in published scientific work.

https://materialvetenskap.uu.se/research/solid-state-physics+/Software/

KKKTON – A program for Kramers-Kronig (KK) analysis of optical data.

Multifresnel_general – A program for thin film optics calculations. Contains the main program library that is needed for all multifresnel programs listed.

Mulifresnel_sol_vis – Incluces solar and luminous values into the optical calculations.

RT_Invert – A program for calculations of optical constants from experimental data. This program uses the mulitfresnel library.

RT_Invert-variant – A program for calculations of optical constants from the raw data files from the spectrophotometer. This program uses the mulitfresnel library.raw data using the mulitfresnel library.

nk-felyta – Calculates all possible optical constants values from experimental data. Can be used as an aid to determine possible solutions. This program uses the mulitfresnel library.

KKKTON – A PROGRAM FOR KRAMERS-KRONIG (KK) ANALYSIS OF OPTICAL DATA.

The KK analysis is carried out using the extinction coefficient (k) as input and the refractive index (n) is calculated. Low energy Drude and high-energy Lorentz extrapolations are used and parameters for these need also to be inputs. The Matlab program contains a routine for calculating reflectance (R) and transmittance (T) for a film on a substrate and comparing with experimental R and T that need to be entered into the program. kdata.txt is an example of an input file of k-data. See attached files for detailed instructions and program files.

Coder: Annette Hultåker

“MULTIFRESNEL_GENERAL” PROGRAM: THIN FILM OPTICS CALCULATIONS.

This program calculates reflectance, back reflectance and transmittance for a stack of thin films on a substrate. The multilayer stack can have an arbitrary number of layers. A thin film optics formalism using layer and interface matrices is used (P. Pfrommer et al. Sol. Energy, vol 54, No 5, pp. 287-299). The layers can be either coherent or non-coherent, while the substrate is always non-coherent.

Inputs are wavelength (nm), refractive index and extinction coefficient (n and k; from files) for each layer and the substrate, as well as thicknesses (nm), angle of incidence and whether the layers are coherent or not. Wavelength interval and substrate thickness can be adjusted directly in the code.

Output data are plotted in a figure and saved in file ”calcspectra.txt”

Warning: Numerical errors can occur for thick substrates with significant absorption.

The main program calls a number of functions, where different parts of the calculations are carried out. These are:

RT_calc.m – Calculates reflectance and transmittance for s-, p- and unpolarized light from the transfer matrix.

transfer_matrix.m – Calculates the transfer matrix of the multilayer.

rt2RT.m – Calculates reflectance and transmittance from reflection and transmission coefficients.

coherent_l.m – Calculates the layer matrix of a coherent layer.

coherent_i.m – Calculates the corresponding interface matrix.

non-coherent_L.m – Calculates the layer matrix of a non-coherent layer.

non-coherent_I.m – Calculates the corresponding interface matrix.

Fresnel_calc.m – Calculates Fresnel reflection and transmission coefficients at an interface for s- and p-polarized light.

theta_calc.m – Calculates the local angle of incidence at each layer.

mult_3D.m – Function for multiplying 3D matrices required for optical calculations.

Note: These functions are also used in all our thin film optics programs on this webpage. By modifying the main program one can use the calculations of the functions for different purposes, for example solving the inverse problem of obtaining optical constants of one layer from experimental data.

MULTIFRESNEL_SOLAR_VIS PROGRAM

This version of the multifresnel program does the same basic calculations as the ”general” version, using the same functions that were supplied with ”multifresnel_general”. However the main program has an additional code that computes solar and luminmous transmittance and reflectance by averaging over the AM1.5 solar spectrum and the luminous eye sensitivity spectrum.

Inputs are wavelength (nm), n and k for each layer, as well as thicknesses (nm) and angle of incidence. The substrate optical constants are also needed. The program needs access, in the same folder, to solar AM1.5 (iso9845tot.txt) and eye sensitivity (eye1.txt) spectra.

Coder: Arne Roos, Anna Werner

RT_INVERT – PROGRAM FOR CALCULATIONS OF OPTICAL CONSTANTS.

These programs fit calculations of reflectance and transmittance for an arbitrary stack of thin films, wherein one layer is unknown, to experimental data. This is done in order to determine the optical constants (refractive index (n) and extinction coefficient (k)) of the unknown layer. Before proceeding to the programs a cautionary note is in order. The inverse problem of thin film optics has multiple solutions and one must be careful to check that the program fits to the physical solution, for example by using independent knowledge of the material under study. Furthermore it is common that the results given by the program cross over from one solution to another one at certain points. This behaviour is especially comon at interference fringes. Hence it may be necessary to perform calculations in different wavelength ranges, in order to obtain the physical solution everywhere. These complications makes determination of optical constants by direct inversion somewhat cumbersome.

The programs listed below all use the MATLAB functions listed in the description of the Multifresnel programs. These must be accessible in the same folder as the main programs listed below.

RT_invert_optconst program

This program calculates optical constants of a coherent or non-coherent layer from an input file containing wavelength, transmittance and reflectance data. The unknown film is situated upon a number of underlayers, which can be either coherent or non-coherent and whose optical constants must be known. The layers are numbered from the top and the substrate is the last underlayer. If number of underlayers is put to zero the remaining layer must be coherent.

Input files are interpolated to the same wavelengths (input data must be given in a wider wavelength region than the interpolation range!). The program uses non-linear least squares fitting starting at the shortest wavelength.

The main program calls the function find_nk as well as RT_calc. The latter one uses the other functions in the multifresnel library.

Input: File with experimental wavelength, transmittance and reflectance. Incidence angle, film thickness and coherence of the unknown layer. Number of underlayers. Optical constants, thickness and coherence of each underlayer.

Output: Figures of n and k; experimental and fitted R and T; deviations between experiment and calculations. Wavelength and calculated n.k are saved in a file.

Coder: Jonas Backholm, Arne Roos (edited by Gunnar Niklasson)

RT_INVERT VARIANT – PROGRAM FOR CALCULATING OPTICAL CONSTANTS

This program is identical to the one above with the following exception: It is intended to be used directly with datafiles from the spectrophotometer. Spectrophotometer measurements start at long wavelengths and proceed to shorter ones. This is often an advantage for the inverse problem, since it is often easier to get good convergence of the calculation at long wavelengths and the problem of multiple solutions is at least less severe. Hence this program uses non-linear least squares fitting starting at the longest wavelength.

The main program calls the function find_nk as well as RT_calc. The latter one uses the other functions in the multifresnel library.

Input: File with experimental wavelength, transmittance and reflectance. Incidence angle, film thickness and coherence of the unknown layer. Number of underlayers. Optical constants, thickness and coherence of each underlayer.

Output: Figures of n and k; experimental and fitted R and T; deviation between experiment and calculations. Wavelength and calculated n.k are saved in a file.

Coder: Jonas Backholm, Arne Roos

NK_FELYTA – CALCULATES ALL POSSIBLE N AND K VALUES. FROM EXPERIMENTAL DATA

This program calculates contours in the n,k-plane pertaining to experimental input values of transmittance and reflectance for each wavelength. Hence the program calculates all n,k values that give those values of R and T and plots them in a figure. The intersections between the R and T contours give all possible solutions of n, k that are compatible with the experimental data. Calculations take long time so it is advisable to use the program for a single or 10-20 wavelengths only.

This type of calculation is especially useful when calculated optical constants fail to reproduce experimental data or when multiple solutions exist and the calculated values cross over from one solution to another. In these cases the contours show which solutions may exist, if for example you are uncertain of whether your solution is the physical one. They also give qualitative guidance on the accuracy of the obtained optical constants. If R and T contours are almost parallel the optical constants will be very uncertain and an intersection may easily be missed due to experimental errors.

The program calls RT_calc and by that all the functions in the Multifresnel library. They are all needed in order to run the program.

Input: An experimental file with transmittance and reflectance data, number of underlayers (substrates), n and k of substrates (Note that the wavelengths must be the same as in the experimental file), thickness and coherence property of the underlayers, angle of incidence.

The output is given as figures appearing on the screen. The video part of the program needs further development. A video movie is played but the figure information is not properly updated in the movie. The video is stored in a file “optcontour” but the frame rate of that movie format seems far too high, so I am not sure if this is useful.

Coder: Jonas Backholm

模拟仿真:太阳能电池研究的利器!

太阳能电池的设计和创新无外乎于两个方面:增强器件的光学吸收性能与增强器件内部的载流子传导收集效率。前者从根本上决定了器件俘获光能的能力,而后者则关乎器件的实际电气输出性能,两者相辅相成,缺一不可。

由于太阳能电池中同时存在光场、电场、载流子分布、边缘界面态等多种相互耦合的物理机制,使得准确预测器件的光电性能变得困难,尤其是在使用了新型的器件构型和光电材料之后。高档次的太阳能电池研究论文往往需要借助计算机模拟仿真来获得器件内部的各种物理信息,为其研究成果提供强有力的理论依据和实验参照。

半导体太阳能电池的计算机仿真技术继承于传统的半导体工艺模拟和器件模拟技术,即TCAD(Technology Computer Aided Design)模拟技术。在传统TCAD软件家族里,最为大家所熟知的两大巨头便是来自Silvaco公司的Silvaco TCAD套装与来自Synopsys公司的Sentaurus TCAD套装。这两款软件包可以实现从半导体器件制造工艺模拟,到分立器件物理特性(电、光、声)仿真,再到电路集成系统性能测试的“全栈式”计算机模拟和设计自动化,因此被广泛使用于现代半导体设计与制造领域,堪称行业标准。其超高的模拟精准度甚至可以用来指导半导体生产线的参数调试。

在光电器件仿真方面,TCAD软件的核心都是先通过各类光学仿真器建立器件内部的稳态光场分布并获得载流子激发速率,再利用有限元分析求解器件内部在指定工作电压下的稳态电场与载流子流场,并最终推算出电极处的光电流强度以及器件的光电能量效率。

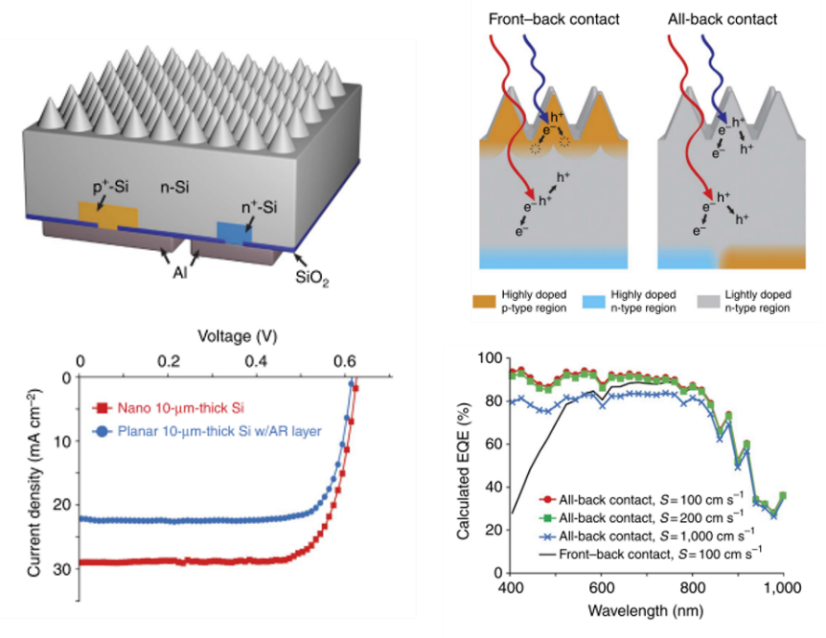

传统TCAD仿真软件至今仍然活跃在以硅太阳能电池为代表的传统光伏器件研究领域。例如斯坦福大学崔毅团队便使用了Sentaurus TCAD计算并指导设计了硅基薄膜背接触太阳能电池,相关研究成果被发表在Nature Communications上 (NATURECOMMUNICATIONS | DOI: 10.1038/ncomms3950)。

图 1使用Sentaurus TCAD模拟模拟硅基太阳能电池,获得伏安曲线、内外量子效率等器件特性参数 (NATURE COMMUNICATIONS | DOI: 10.1038/ncomms3950)

随着纳米材料和微纳尺寸器件构型在太阳能电池领域的兴起,光学设计的重要性日益突出。一方面,由于纳米块材,如纳米线、纳米柱等,在空间上天然的稀疏性,或者因为纳米晶薄膜材料中有限的载流子传递效率对材料厚度的巨大限制(通常在几百纳米以内),导致这类器件在光能吸收方面可能有先天的不足。而另一方面,合理使用微纳结构的光学共振特性,能显著提高器件对共振波段的有效吸收,甚至还有可能在光学性能上超越一般的块材器件。

在这样的背景下,传统TCAD软件普遍采用的基于光线追踪(Ray Trace)算法的光学仿真器变得不再适用,与此同时一类更加注重器件微纳光学性能计算,精简载流子输运模拟的仿真模式开始在太阳能电池领域兴起。例如Lumerical公司的FDTD(Finite-differencetime-domain)光学仿真器便是其中的代表。得益于对麦克斯韦方程的直接(数值)求解,这类仿真模式能更加准确地还原器件的各类光学模式和载流子激发分布,尤其在对拥有光子晶体、表面等离子激元等光学现象的器件上有突出的表现。

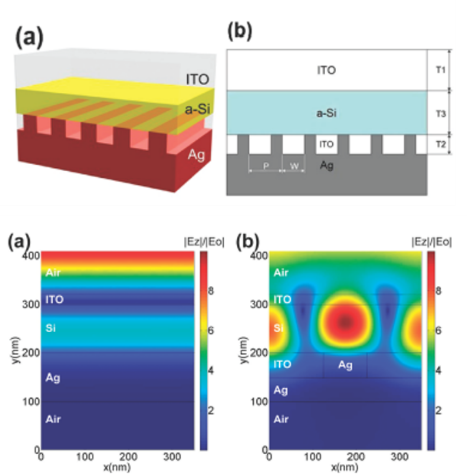

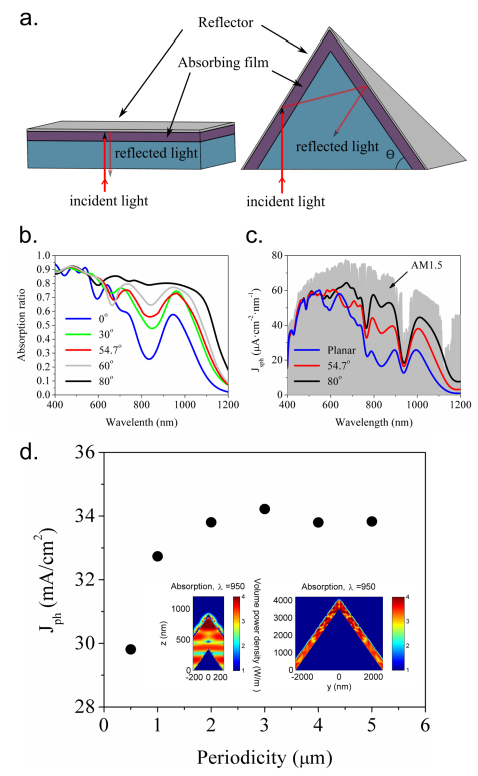

下面介绍的这一篇来自美国德州奥斯汀分校Shaochen Chen团队的Nano Letters(Nano Lett |DOI: 10.1021/nl904057p)便是一篇时间相对较早的代表性论文。在这篇文章中,研究人员使用了FDTD光学仿真探究了使用金属条栅结构在薄膜电池中获得广谱、广角、偏振不敏感的光吸收增强的可能。其背后的物理机理便是充分利用了薄膜器件中Fabry – Perot共振、平面波导以及金属条栅的表面等离子激元等多种光学模式。而FDTD模拟成为了揭示这一作用机理的利器。

图 2使用FDTD光学模拟准确获取薄膜太阳能电池中的光学模式(Nano Lett |DOI: 10.1021/nl904057p)

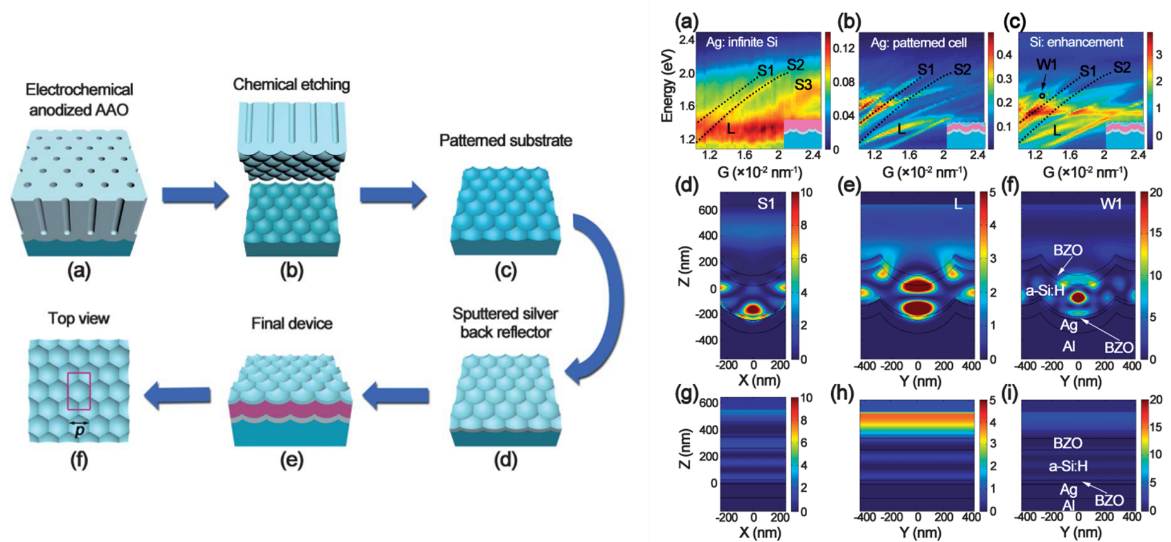

在实验方面,香港科技大学范志勇教授团队使用纳米拓印技术将类似上述的器件设计理念应用于超薄非晶硅电池的设计创新中,成功使器件的光学性能获得了约30%的提升,相关研究成果被刊发在顶级神刊物EES上(Energy Environ. Sci| DOI: 10.1039/c3ee41139g)。这里,FDTD光学模拟同样在器件设计指导与论文理论说明上提供了强有力的支撑。

图 3使用FDTD光学模拟还原使用复杂器件构型下的内部光场信息 (Energy Environ.Sci| DOI: 10.1039/c3ee41139g)

对于基于纳米线\柱构型的太阳能电池而言,准确计算预测纳米线\柱结构中的光学共振模式,如Mie共振模式和波导模式,是获得优质光学吸收性能的一大前提。

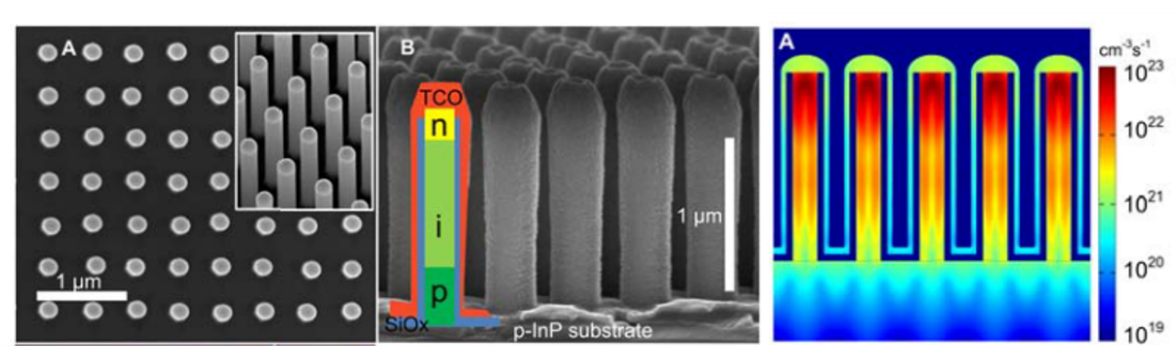

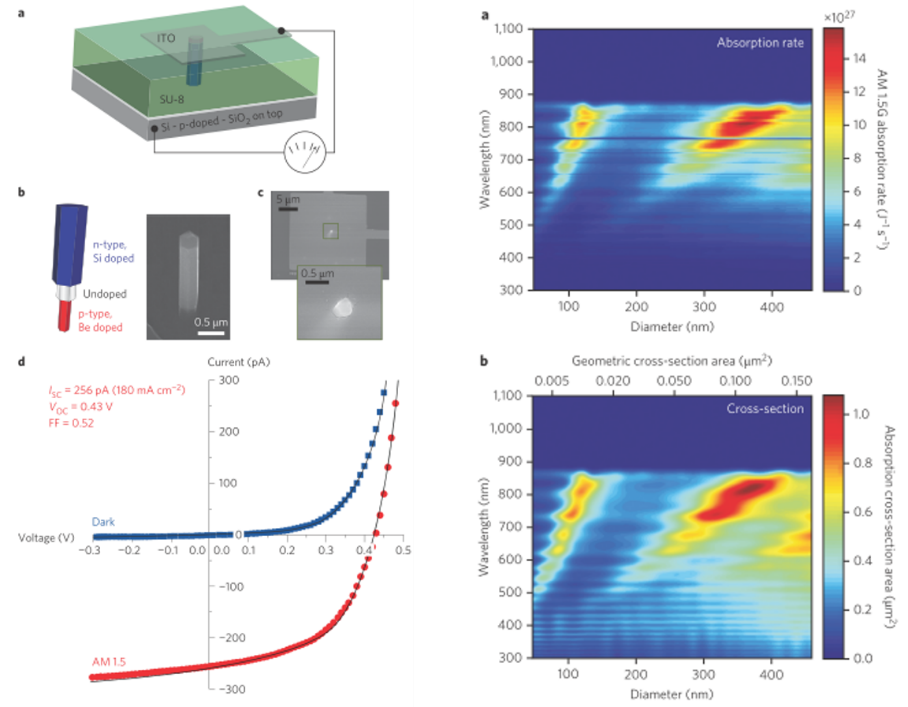

在这篇曾经引领一时风潮的InP纳米线太阳能电池的报道中(Science|DOI: 10.1126/science.1230969),瑞典兰德大学MagnusT. Borgström教授团队就使用了散射矩阵(scattering matrix)法计算了InP纳米线阵列中的光场分布以及每根纳米线内部相应的载流子激发率。这些模拟结果成为其论证纳米线太阳能电池光学性能的重要理论依据。

图 4 使用光学模拟技术获取InP纳米线阵列中的载流子激发率分布(Science|DOI: 10.1126/science.1230969)

而后来更为登峰造极的经典之作当属下面这篇来自丹麦哥本哈根大学Anna Fontcuberta i Morral教授团队的NaturePhotonics(NATURE PHOTONICS|DOI: 10.1038/NPHOTON.2013.32)。在这篇文章中,研究团队使用了一根看似平淡无奇的p-i-n核-壳(core-shell)纳米单线,通过利用纳米线的Mie共振模式,获得了对太阳光谱有针对性的增强吸收,最终在标准光谱下(AM1.5)实现了超越Shockley–Queisser极限的器件转换效率!助其完成光学理论验证与说明的正是更为精准和完备的FDTD光学仿真。

图 5使用FDTD光学仿真设计单纳米线太阳能电池,获得超越Shockley–Queisser极限的器件转换效率(NATURE PHOTONICS|DOI: 10.1038/NPHOTON.2013.32)

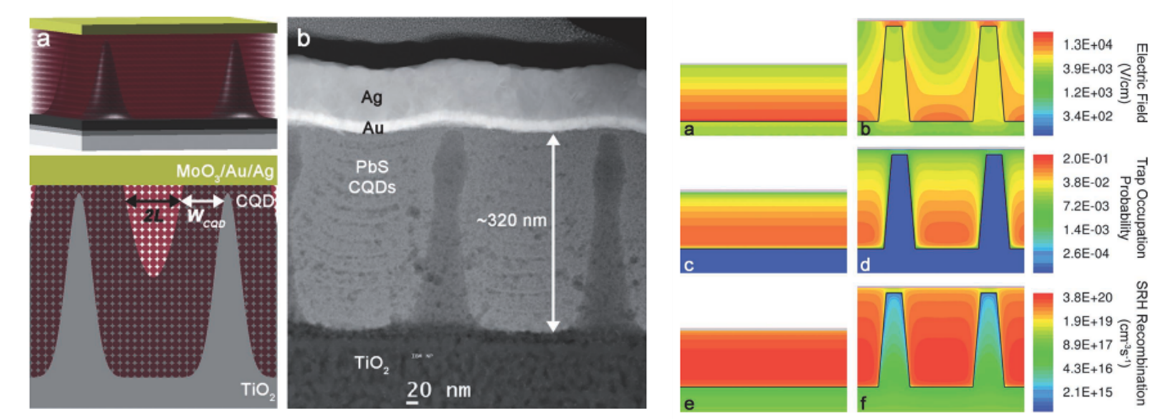

在以量子点薄膜为代表的新兴薄膜材料电池领域,计算机仿真同样在增强薄膜的整体光学吸收性能和载流子输运效率方面显现出强大的指导能力和实用价值。

以量子点电池闻名于世界的多伦多大学Sargent教授课题组自2014年以来,多次在Nano Letters, ACS Nano等顶级期刊上发表有关利用量子点薄膜整体构型来提升其光学吸收性能的研究成果,而其背后同样使用了大量的FDTD光学仿真来论证支持他们的设计。

(NanoLetters|DOI: 10.1021/nl504086v,

ACSNano|DOI: 10.1021/acsnano.5b01296,

NanoLetters|DOI: 10.1021/acs.nanolett.6b05241)

图 6利用FDTD仿真,计算复杂量子点薄膜构型的光学吸收性能(Nano Letters|DOI:10.1021/nl504086v)

而在Sargent课题组更早期一点的研究中(Advance Material| DOI:10.1002/adma.201104832),他们更是借助了Sentaurus TCAD器件仿真来研究纳米柱构型的电极结构在量子点薄膜中收集载流子的能力,成为当时研究纳米晶薄膜电池载流子输运效率的经典之所。

图 7使用Sentaurus TCAD研究了纳米柱构型的电极结构在量子点薄膜中收集载流子的能力(Advance Material| DOI:10.1002/adma.201104832)

总结一下,太阳能电池的器件仿真可以帮助我们获得器件内部准确的光场与载流子激发分布,并可以进一步计算出器件内部的载流子收集传输情况,获得器件的完整伏安工作特性。以此为基础,太阳能电池的四大基础参数,即短路电流、开路电压、填充因子和能量效率,都可以计算得出。在光学仿方面,微纳尺寸构型的太阳能电池应该充分考虑其中的光学共振模式所带来的影响。借助器件模拟技术,可以为器件的形貌设计和材料选择提供坚实的理论指导。

通过上面介绍过的例子我们看到,半导体器件模拟仿真在太阳能电池研究领域的巨大作用。优质的器件仿真可以显著提高研究成果的理论完备性。