Diamond Centre Wales: Laser engraved nano-markings (2020)

“We strongly believe that nano marking using laser scribing, with photonics to uniquely mark the diamonds in a non-destructive way, is the answer for secure tracing and identification. Working with CPE partner Bangor University has clearly showed this is possible in their feasibility study, and we would look forward to working with them again to fully explore this innovative process”

Kelvin James (MD), Diamond Centre Wales

Diamond Centre Wales are registered Diamond Merchants and bespoke jewellery manufacturers based in South Wales. Their expert team comprises of artists, designers, diamond graders and Goldsmiths, who create over 1000 bespoke pieces each year.

Currently there is no standard practice to intercept stolen goods during re-sale making it very difficult to recover lost or stolen high value diamonds. DCW have a solution through Seculuxe, which aims to combat this using blockchain technology and proprietary diamond laser engraving techniques to create a unified standard for high-value jewellery recovery and identification.

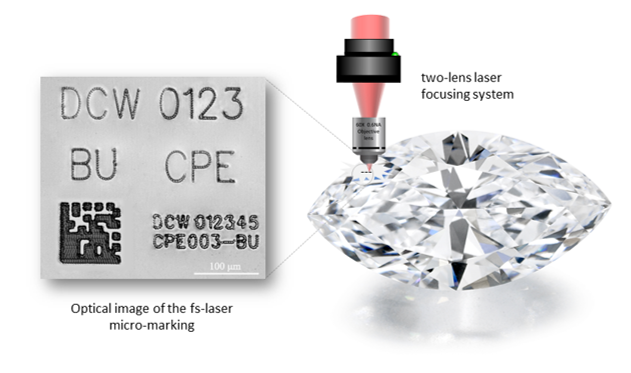

Initial research at Bangor University led to the development of a very quick and clean solution by using focused ultrafast laser pulses to write text and labels in variable size and shapes on any surface of the polished diamond sample. Several geometries were scribed on the diamond surface including QR codes, letters and text to simulate typical laser marked serial numbers as shown in the image. The size of the diamond is roughly 3x2x2 mm3.

The height of the text as shown by “DCW” is about 60 µm. The maximum depth of the laser machined line is 0.29 µm measured from surface plane of the untreated diamond. The results demonstrate a close agreement to the size requirements of the client to mark thin areas of polished diamonds such as girdle or crown. The pavilion marking shown in Figure as “CPE003-BU” is about 25 µm high (girdle height ~100 µm).

In the next stage of the collaboration the Bangor team hope to implement their unique PCM superlens to create smaller markings. The company’s aim is to build capacity for rapid manufacturing of marked diamonds in their product line. These marked diamonds will be linked to a central database (local or global) for their quick identification and tracking when required, especially in case of theft or loss.

Welsh Slate: Automated product counting system

“Bangor University CPE team have invested significant time and resources into solving this problem by successfully implementing photonics and bespoke programming. Welsh Slate are looking forward to advancing the project further with Bangor University, with the aims of improving accuracy and implementing pattern recognition, ensuring the system will be able to run successfully in the production environment”

Dylan Evans (Project Engineer), Welsh Slate

Welsh Slate is the world’s leading manufacturer and supplier of high-quality slate for a peerless range of exterior and interior design applications. Uniquely 500 million years old, the material is widely recognized as the finest natural slate in the world. Operating in four locations in the UK, today, Welsh Slate continues to producing roofing slate, architectural products and aggregates while its export markets continue to grow.

The company has been interested in using photonics technology to improve and optimize their existing manufacturing processes, thus increasing productivity and reducing costs. This project aims to develop an demonstration prototype of Automated-Slate-Counting System (ASCS) for the company. This will be used to replace existing manual counting system, which is time-consuming, costly and prone to error. It is expected further project will continue after this project to explore the improvement and implementation of ASCS in the manufacturing line of Welsh Slate.

The slates produced follow a rather complex packaging and manual counting which is tedious and time consuming task for hundreds of slates. Through CPE, a project was initiated by collaboration of Bangor University (BU) and Welsh Slate to develop a feasible solution for a quick and accurate counting of the slates. Initial research at BU led to the development of an automated counting program with capability of accurate counting of a packaging in few seconds only compared to several minutes in the previous practice.